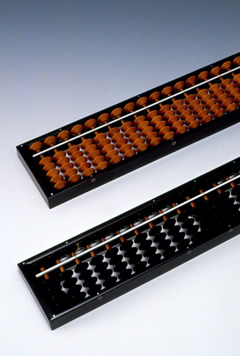

UNSHU Soroban (Abacus)

Toward the end of the Edo era (1600-1868), a carpenter living in Shimane Prefecture obtained an abacus made by a specialist from Hiroshima. Using this abacus as a model, he made his own from locally sourced oak, Japanese apricot and smoked bamboo (susudake).

Later, craftsmen from the district of Yokota-cho perfected a hand lathe for making abacus beads, which substantially increased production and created the foundation for today's small craft industry. The abacuses produced here are of such high quality that the name Unshu is practically synonymous with abacuses.

The most important element of an abacus is the beads, which should move freely and produce a clear click when they strike the frame or another bead. Careful attention is paid to the finish of the bamboo shafts and the holes of the beads. Unshu abacuses are characterized by how they improve in quality the longer they are used.

Feature

Beads are the primary component of abacuses. The best abacuses have beads that move well and make a very clear sound. Because great care is used to finish the bamboo shafts and the holes of the beads, the quality actually improves the longer they are used.

How to make

The frame is made of ebony or specially reinforced wood, the shaft is made from smoked or processed bamboo and the beads are made from birch, boxwood or ebony. All materials are inspected and only those that are sufficiently dry and free of warping are used.